- 1. K.LOHITHA

PA/2016/106

National Institute of Pharmaceutical

Education and Research (NIPER)

Pharmacopoeial methods of Analysis

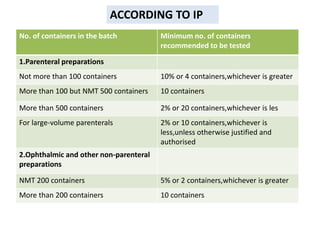

- 2. Sterility – Process of removing all viable forms of microorganisms.

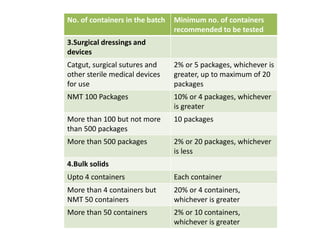

Sterility test – A test that critically assesses whether a sterilized pharmaceutical

product is free from contaminating microorganisms.

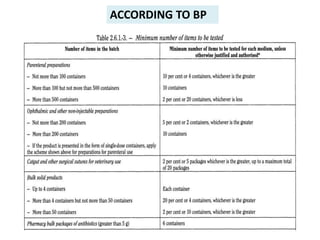

(or)

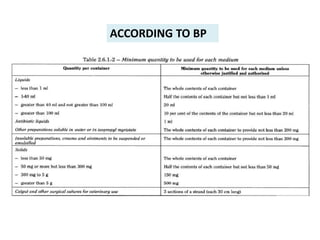

Acc to IP – The sterility tests are intended for testing the absence of viable forms of

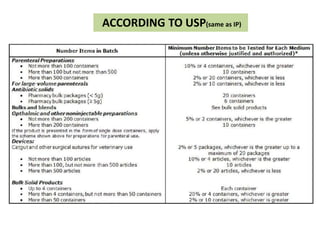

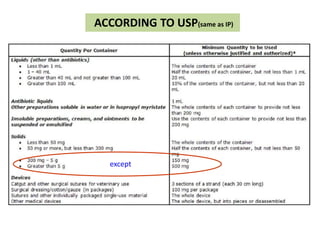

microorganisms in or on the pharmacopeial preparations.

- 3. Products which are necessary to be sterilized :

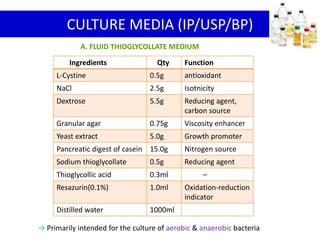

• Injections

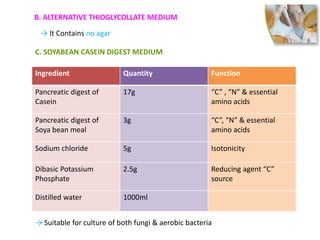

• Implants

• Syringes

• Ophthalmic preparations

• Ointments & creams

• Bandages

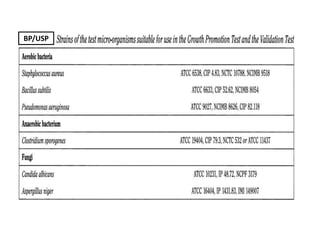

• Surgical dressings & devices

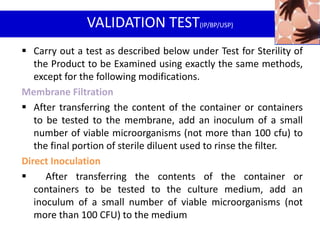

• needles

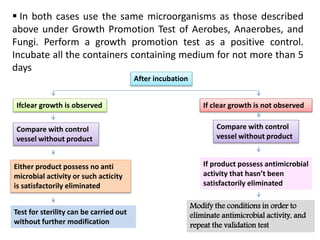

- 4. • These tests are based upon the principle that if micro-

organisms (present in the sample) are placed in a medium

which provides nutritive material and water, and kept at a

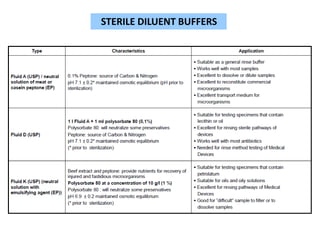

favorable temperature, the organisms will grow and their

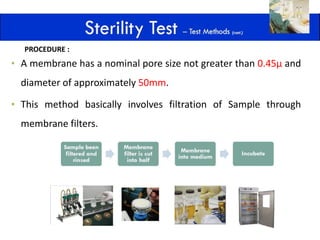

presence can be indicated by a turbidity in the originally clear

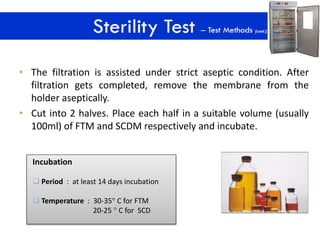

medium.

• The interpretation of results is based on the assumption that

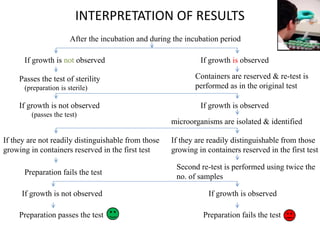

the contents of every container in the batch, had they been

tested, would also have given the same results.

• Since every container cannot be tested, a sufficient number of

containers should be examined to give a suitable degree of

confidence in the results of the tests.

PRINCIPLE

- 5. No. of containers in the batch Minimum no. of containers

recommended to be tested

1.Parenteral preparations

Not more than 100 containers 10% or 4 containers,whichever is greater

More than 100 but NMT 500 containers 10 containers

More than 500 containers 2% or 20 containers,whichever is les

For large-volume parenterals 2% or 10 containers,whichever is

less,unless otherwise justified and

authorised

2.Ophthalmic and other non-parenteral

preparations

NMT 200 containers 5% or 2 containers,whichever is greater

More than 200 containers 10 containers

ACCORDING TO IP

- 6. No. of containers in the batch Minimum no. of containers

recommended to be tested

3.Surgical dressings and

devices

Catgut, surgical sutures and

other sterile medical devices

for use

2% or 5 packages, whichever is

greater, up to maximum of 20

packages

NMT 100 Packages 10% or 4 packages, whichever

is greater

More than 100 but not more

than 500 packages

10 packages

More than 500 packages 2% or 20 packages, whichever

is less

4.Bulk solids

Upto 4 containers Each container

More than 4 containers but

NMT 50 containers

20% or 4 containers,

whichever is greater

More than 50 containers 2% or 10 containers,

whichever is greater

- 7. ACCORDING TO IP

- 8. ACCORDING TO BP

- 9. ACCORDING TO BP

- 10. ACCORDING TO USP(same as IP)

- 11. ACCORDING TO USP(same as IP)

except

- 12. Ingredients Qty Function

L-Cystine 0.5g antioxidant

NaCl 2.5g Isotnicity

Dextrose 5.5g Reducing agent,

carbon source

Granular agar 0.75g Viscosity enhancer

Yeast extract 5.0g Growth promoter

Pancreatic digest of casein 15.0g Nitrogen source

Sodium thioglycollate 0.5g Reducing agent

Thioglycollic acid 0.3ml –

Resazurin(0.1%) 1.0ml Oxidation-reduction

indicator

Distilled water 1000ml

A. FLUID THIOGLYCOLLATE MEDIUM

CULTURE MEDIA (IP/USP/BP)

→ Primarily intended for the culture of aerobic & anaerobic bacteria

- 13. Ingredient Quantity Function

Pancreatic digest of

Casein

17g “C” , “N” & essential

amino acids

Pancreatic digest of

Soya bean meal

3g “C”, “N” & essential

amino acids

Sodium chloride 5g Isotonicity

Dibasic Potassium

Phosphate

2.5g Reducing agent “C”

source

Distilled water 1000ml

→ It Contains no agar

B. ALTERNATIVE THIOGLYCOLLATE MEDIUM

C. SOYABEAN CASEIN DIGEST MEDIUM

→ Suitable for culture of both fungi & aerobic bacteria

- 14. MEDIA SUITABILITY TEST

Media is sterile

Prior to test, make sure that :

Media supports growth of microorganisms

2 components in Media suitability test :

Media sterility test

Growth Promotion test

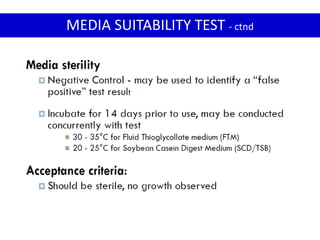

- 15. MEDIA SUITABILITY TEST - ctnd

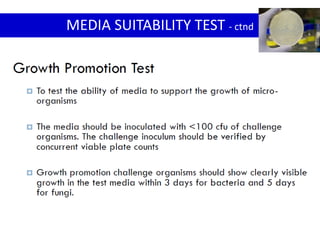

- 16. MEDIA SUITABILITY TEST - ctnd

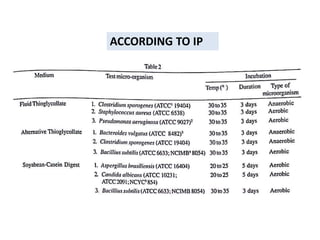

- 17. ACCORDING TO IP

- 18. BP/USP

- 19. VALIDATION TEST(IP/BP/USP)

Carry out a test as described below under Test for Sterility of

the Product to be Examined using exactly the same methods,

except for the following modifications.

Membrane Filtration

After transferring the content of the container or containers

to be tested to the membrane, add an inoculum of a small

number of viable microorganisms (not more than 100 cfu) to

the final portion of sterile diluent used to rinse the filter.

Direct Inoculation

After transferring the contents of the container or

containers to be tested to the culture medium, add an

inoculum of a small number of viable microorganisms (not

more than 100 CFU) to the medium

- 20. In both cases use the same microorganisms as those described

above under Growth Promotion Test of Aerobes, Anaerobes, and

Fungi. Perform a growth promotion test as a positive control.

Incubate all the containers containing medium for not more than 5

days

After incubation

Ifclear growth is observed If clear growth is not observed

Compare with control

vessel without product

Either product possess no anti

microbial activity or such acticity

is satisfactorily eliminated

If product possess antimicrobial

activity that hasn’t been

satisfactorily eliminated

Test for sterility can be carried out

without further modification

Modify the conditions in order to

eliminate antimicrobial activity, and

repeat the validation test

Compare with control

vessel without product

- 21. This validation is performed

(a)when the test for sterility has to be carried out on a new

product; and

(b whenever there is a change in the experimental conditions of

the test. The validation may be performed simultaneously

with the Test for Sterility of the Product to be Examined

VALIDATION TEST - ctnd

- 22. It is preferred where the substance under examination is :

• An oil

• An ointment that can be put into the solution

• A non bacteriostatic solid not readily soluble in the

culture medium.

• A soluble powder or a liquid that possess inherent

bacteriostatic or fungistatic properties.

• For liquid products where the volume in a container

is 100m1 or more.

A. MEMBRANE FILTRATION

- 23. STERILE DILUENT BUFFERS

- 24. • A membrane has a nominal pore size not greater than 0.45μ and

diameter of approximately 50mm.

• This method basically involves filtration of Sample through

membrane filters.

PROCEDURE :

- 25. • The filtration is assisted under strict aseptic condition. After

filtration gets completed, remove the membrane from the

holder aseptically.

• Cut into 2 halves. Place each half in a suitable volume (usually

100ml) of FTM and SCDM respectively and incubate.

Incubation

Period : at least 14 days incubation

Temperature : 30-35° C for FTM

20-25 ° C for SCD

- 26. It is the more traditional sterility test method. Basically, it

involves 3 steps:

1. Aseptically opening each sample container from a recently

sterilized batch of product.

2. Using a sterile syringe and needle to withdraw the required

volume of sample for both media from the container

3. Injecting one-half of the required volume sample into a test

tube containing the required volume of FTM and the other

half volume of sample into a second test tube containing the

required volume of SCD and incubating both.

B. DIRECT INNOCULATION

- 27. After the incubation and during the incubation period

If growth is not observed If growth is observed

Passes the test of sterility

(preparation is sterile)

Containers are reserved & re-test is

performed as in the original test

If growth is not observed

(passes the test)

If they are not readily distinguishable from those

growing in containers reserved in the first test

Preparation fails the test

If growth is not observed

Preparation passes the test

INTERPRETATION OF RESULTS

microorganisms are isolated & identified

If growth is observed

If they are readily distinguishable from those

growing in containers reserved in the first test

Second re-test is performed using twice the

no. of samples

If growth is observed

Preparation fails the test

- 28. REFERENCES

INDIAN PHARMACOPOEIA2014,

VOLUME 1(59-66)

UNITED STATES PHARMACOPOEIA

2013, VOLUME 1(71-76)

BRITISH PHARMACOPOEIA2009,

VOLUME 4(Appendix XVI)