- 1. ON

DESIGN AND ANALYSIS OF

REPLACING

LEAF SPRINGS

WITH

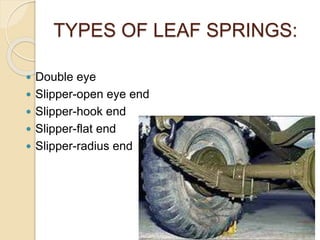

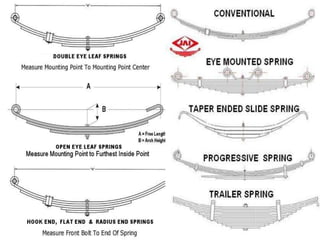

COMPOSITE LEAF SPRING

Submitted by

D.SantoshKumar

.

Under Guidance of

Prof:P.Ravindhra Babu(M.s, Ph.d, vice principa

Gudlavalleru Engineering College

- 2. TOPICS:

INTRODUCTION

LEAF SPRINGS

COMPOSITE MATERIALS

COMPOSITE LEAF SPRINGS

ANALYSIS AND RESULTS

MERITS AND DEMERITS

- 3. INTRODUCTION:

Composite materials are the one of the main

applications of the aerospace, automobiles and

marine Industries. Because of their less weight,

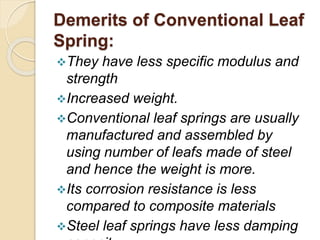

good stiffness and less corrosive properties.

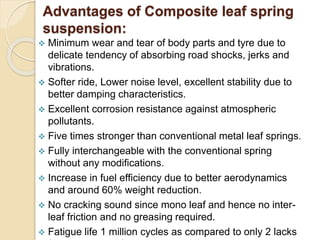

Weight reduction is one of the major factors of

that one. It results in less fuel consumption;

economize maintenance of vehicle and optimum

utilization of natural resources. The suspension

leaf spring is one of the potential items for

weight reduction in

automobile

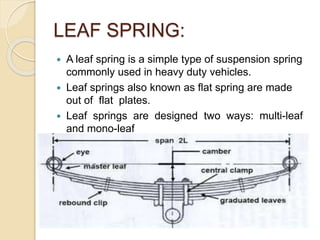

- 4. LEAF SPRING:

A leaf spring is a simple type of suspension spring

commonly used in heavy duty vehicles.

Leaf springs also known as flat spring are made

out of flat plates.

Leaf springs are designed two ways: multi-leaf

and mono-leaf

- 5. TYPES OF LEAF SPRINGS:

Double eye

Slipper-open eye end

Slipper-hook end

Slipper-flat end

Slipper-radius end

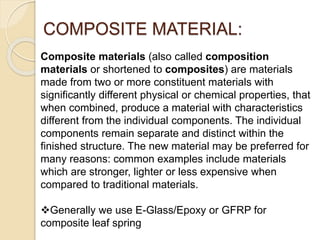

- 7. COMPOSITE MATERIAL:

Composite materials (also called composition

materials or shortened to composites) are materials

made from two or more constituent materials with

significantly different physical or chemical properties, that

when combined, produce a material with characteristics

different from the individual components. The individual

components remain separate and distinct within the

finished structure. The new material may be preferred for

many reasons: common examples include materials

which are stronger, lighter or less expensive when

compared to traditional materials.

Generally we use E-Glass/Epoxy or GFRP for

composite leaf spring

- 8. E-Glass/Epoxy or GFRP:

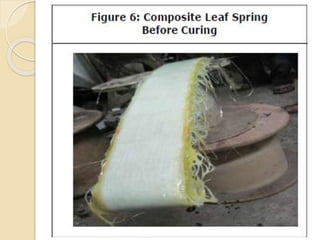

- 9. COMPOSITE LEAF

SPRINGS:

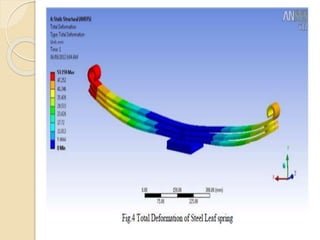

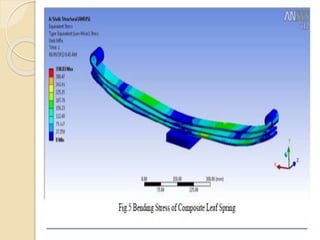

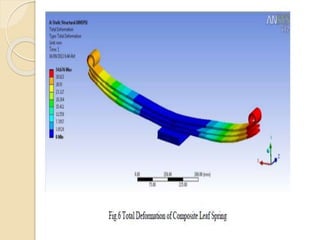

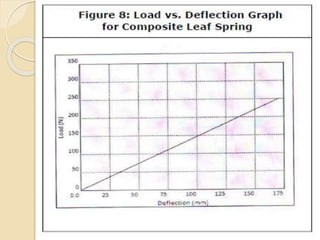

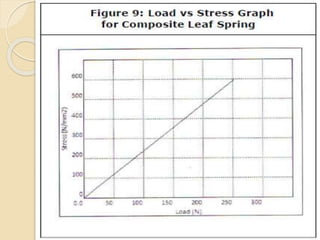

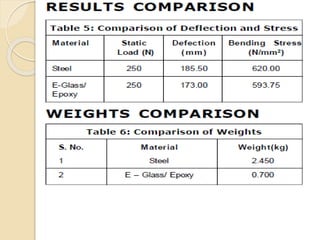

- 12. ANLYSIS AND RESULTS:

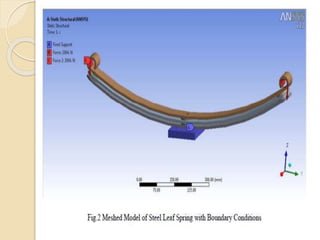

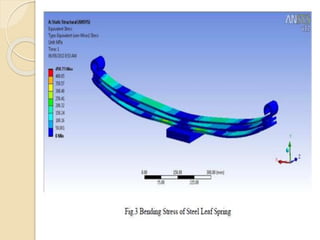

Leaf Spring is Modeled in PRO-E and it is

imported to ANSYS and then it is subjected to

different load conditions and changes like

Stress,Strain,Bending Von Mises Stress,

Deformation will be taken as graphs and Ansys

results We analyze the variations from values

shown by ansys.We compare parameters of

both leaf spring and composite leaf spring.

Some of the ansys and tabular results are

shown below

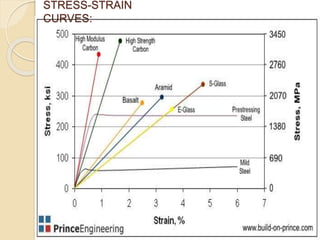

- 18. STRESS-STRAIN

CURVES:

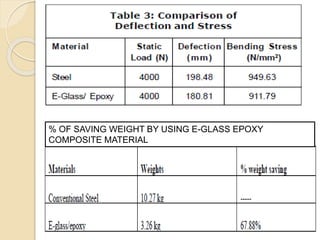

- 22. % OF SAVING WEIGHT BY USING E-GLASS EPOXY

COMPOSITE MATERIAL

- 23. Demerits of Conventional Leaf

Spring:

They have less specific modulus and

strength

Increased weight.

Conventional leaf springs are usually

manufactured and assembled by

using number of leafs made of steel

and hence the weight is more.

Its corrosion resistance is less

compared to composite materials

Steel leaf springs have less damping

- 24. Advantages of Composite leaf spring

suspension:

Minimum wear and tear of body parts and tyre due to

delicate tendency of absorbing road shocks, jerks and

vibrations.

Softer ride, Lower noise level, excellent stability due to

better damping characteristics.

Excellent corrosion resistance against atmospheric

pollutants.

Five times stronger than conventional metal leaf springs.

Fully interchangeable with the conventional spring

without any modifications.

Increase in fuel efficiency due to better aerodynamics

and around 60% weight reduction.

No cracking sound since mono leaf and hence no inter-

leaf friction and no greasing required.

Fatigue life 1 million cycles as compared to only 2 lacks

- 25. Any Queries